Wafer Surface Particle Scanner

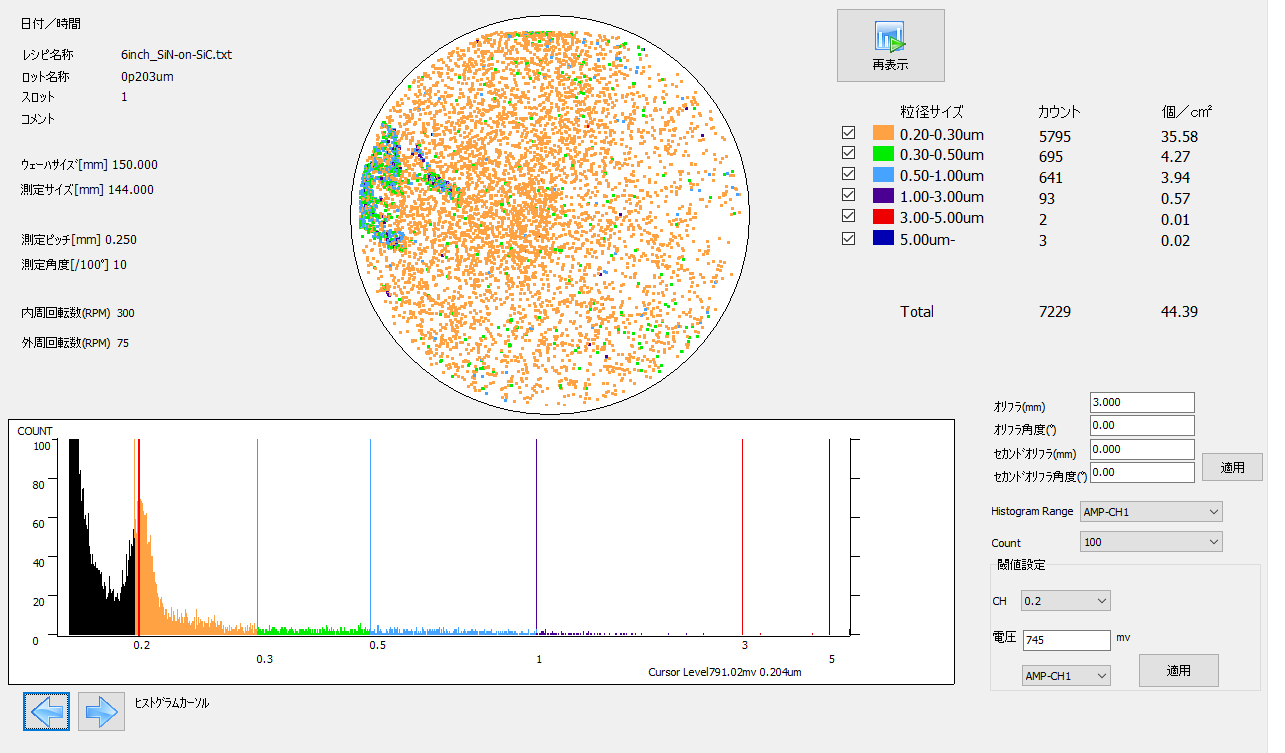

Inspection for Compound & Transparent Wafers

High-Performance Inspection for Unpatterned Transparent and Opaque Wafers

Eumetrys delivers leading-edge solutions for surface inspection and particle detection on unpatterned wafers used in compound semiconductor fabrication. Our flagship system, the YPI – Clear Scanner™, is a versatile wafer surface particle scanner designed to detect submicron particles, haze, scratches, and area defects on a wide range of wafer types — from transparent and semi-transparent substrates to thin and bowed wafers.

In collaboration with YGK, a Japanese manufacturer with over 20 years of experience, Eumetrys provides exclusive global access to this advanced tool. The system plays a critical role in improving yield, cleanliness control, and defect prevention in high-value semiconductor production.

Wafer Surface Particle Scanner for Compound Semiconductor Inspection

YPI – Clear Scanner™: Flexible and Powerful Particle Inspection for Compound Wafers

Particles inspection for transparent substrates

Engineered for flexibility, the YPI – Clear Scanner™ supports wafer diameters ranging from 2” to 12”, while accommodating both standard and advanced materials such as: SiC, GaN, GaAs, InP, Sapphire, Silicon, Glass, and LiNO3.

Its high-resolution laser scanning system enables accurate surface particle inspection, particularly for transparent wafers : a growing need in wide bandgap semiconductor manufacturing.

The system combines:

• Optical optimization for transparent and semi-transparent substrates

• Mechanical stability for bowed or ultra-thin wafers

• Broad defect detection from particles as small as 0.1 µm up to macroscopic surface issues

Such capabilities make the YPI – Clear Scanner™ a crucial component in process control, incoming material verification, and cleanroom contamination monitoring.

YPI – Clear Scanner™ – DC: Dual Channel Inspection for Transparent Wafer Surfaces

For advanced use cases requiring maximum sensitivity, the YPI – Clear Scanner™ – DC adds a dual detection channel system with 355 nm lasers to enhance visibility on transparent and low-contrast wafers. This model supports:

• Optional second optical head to improve particle discrimination

• Raster (XY) or helical scan modes, compatible with circular and square substrates

• Modular customization for specific fab configurations and integration needs

Its precision makes it particularly effective for controlling SiC and GaN wafer quality post-epitaxy, and for monitoring process-induced surface changes in polishing or thin film deposition.

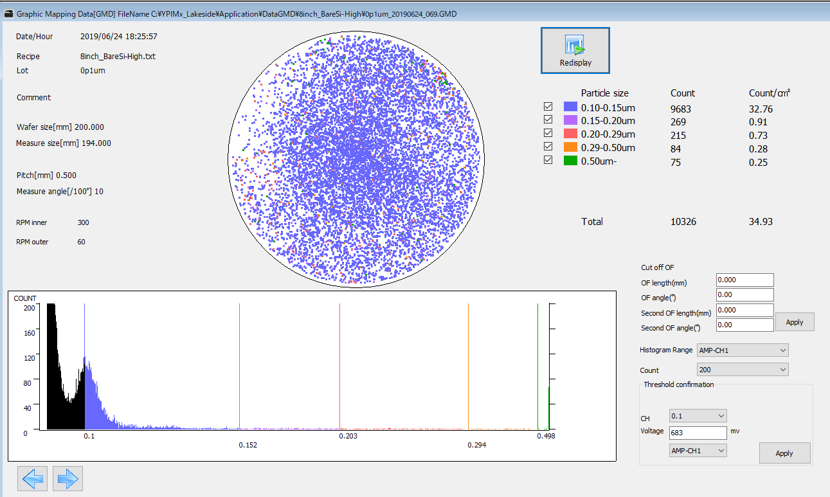

YPI-MX for semiconductor industries

Particle inspection for transparent and opaque substrates

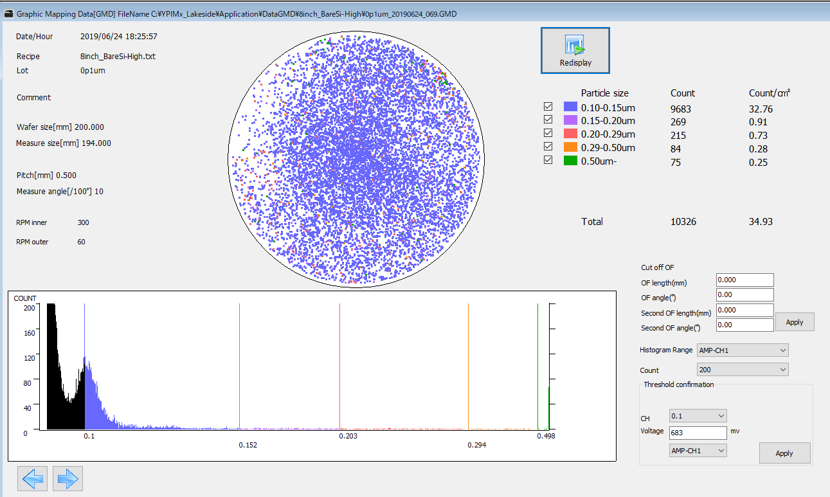

YPI-MX model can detect contamination of particles up to 0.1µm on a great variety of substrates up to 8 inches. It performs measures on Si, Crystal, Saphire, LiNb03 or LiTa03 thanks to its 405nm laser. It is possible to add a second optical head to improve measurement accuracy. Applications for this tool are wide:

- Process control

- Wafer contamination control, including EPI and SiC wafers and thin layers

- Equipment contamination control

- Polishing process control

- Wafer reception control, coming from your suppliers

YPI-MX has another advantage. It can perform two types of scan: raster (XY) or helical sweeps. We recommend to use XY sweep for wafers and square substrate, the helical one being only for wafers.

Do not hesitate to contact us to get a technical brochure by clicking here

YPI-MX, a versatile and customizable equipment

The two lasers offer a better measurement accuracy but also reduce surface effect such as roughness. This technology detects particle up to 0.1µm. Standard edge exclusion is 3mm. The equipment is designed for both standard and specific applications.

The tool has a standard loading port as well as an automatic handling robot. This robot can charge wafers from 50mm to 200mm. In option, you can add loading ports and install a double hand robot.

It is also possible to embed an optical microscope to manually visualize particles. 20x and 50x mag allows to observe particles of respectively 3µm and 1µm. The camera transcribes in color, an image of 4 million of pixels. Furthermore, we offer an automatized particle follow-up option. It gives an interactive map to select and visualize particles thanks to the optical microscope. Save and analyze results directly from your office.

Do not hesitate to contact us to get a technical brochure by clicking here