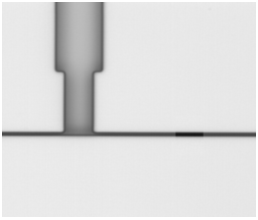

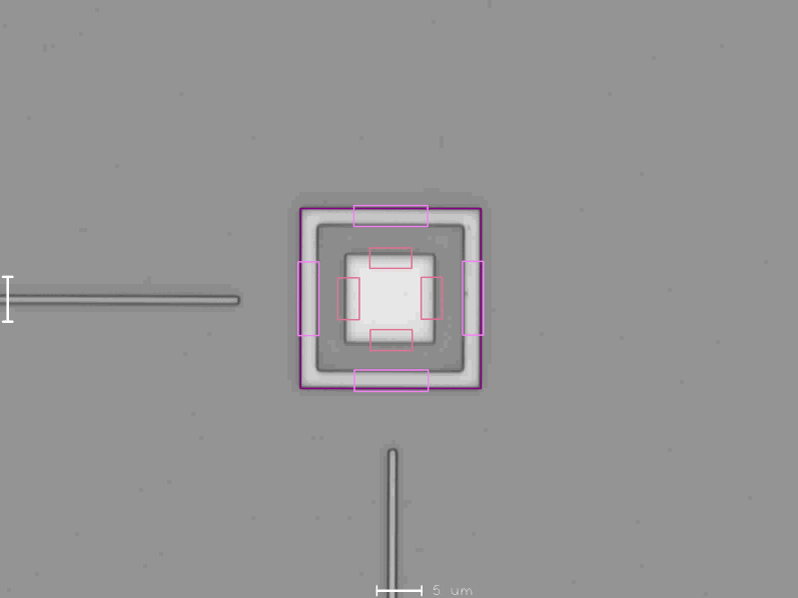

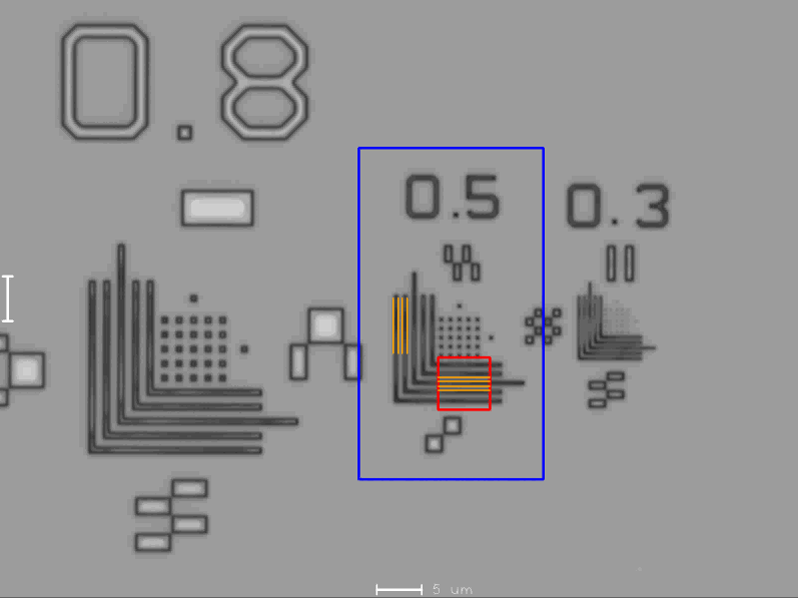

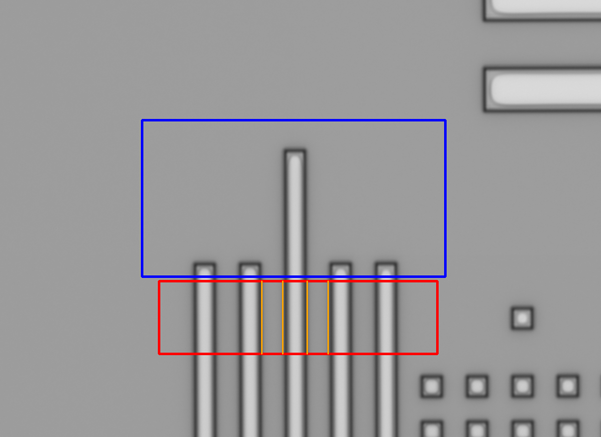

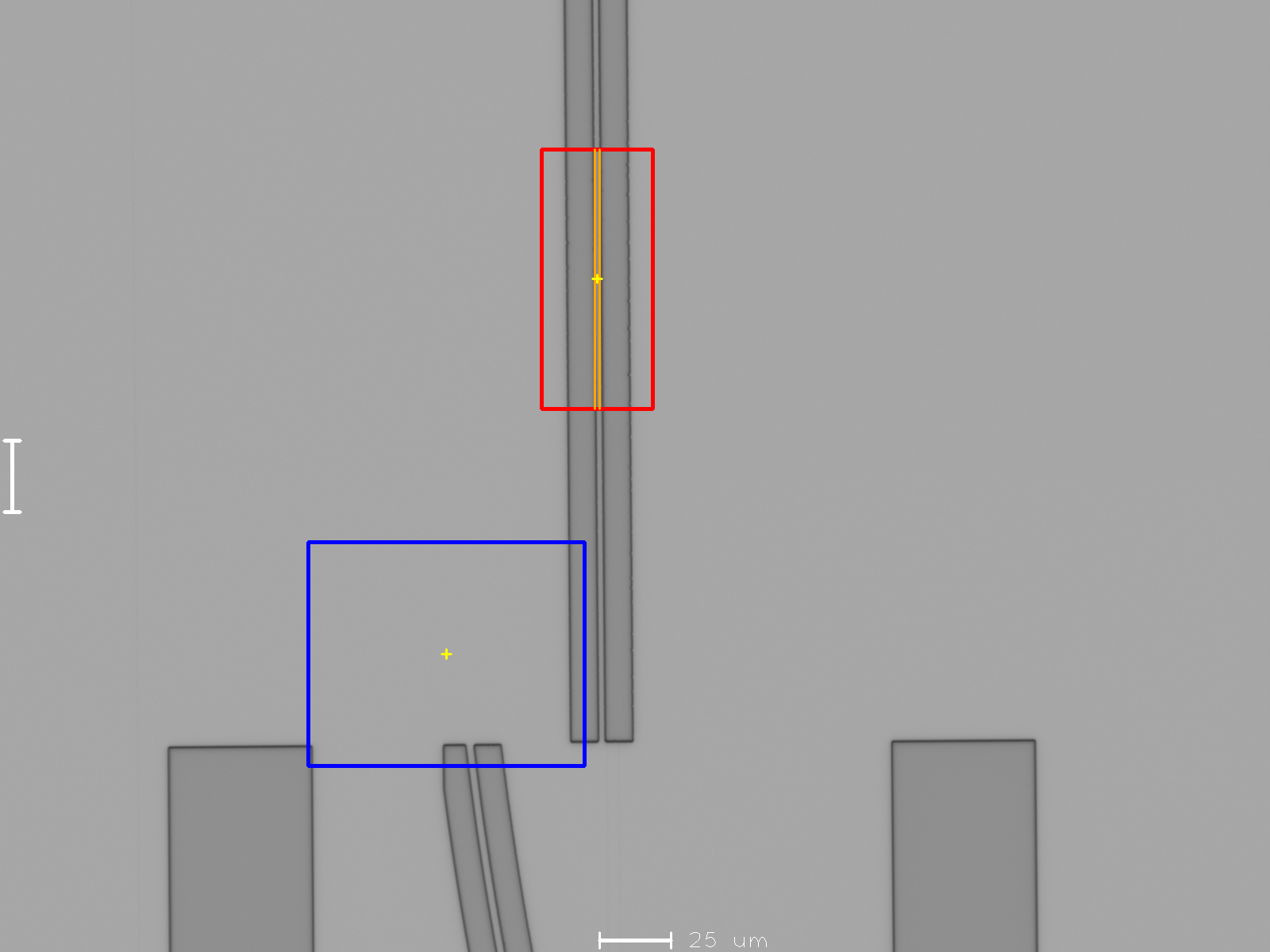

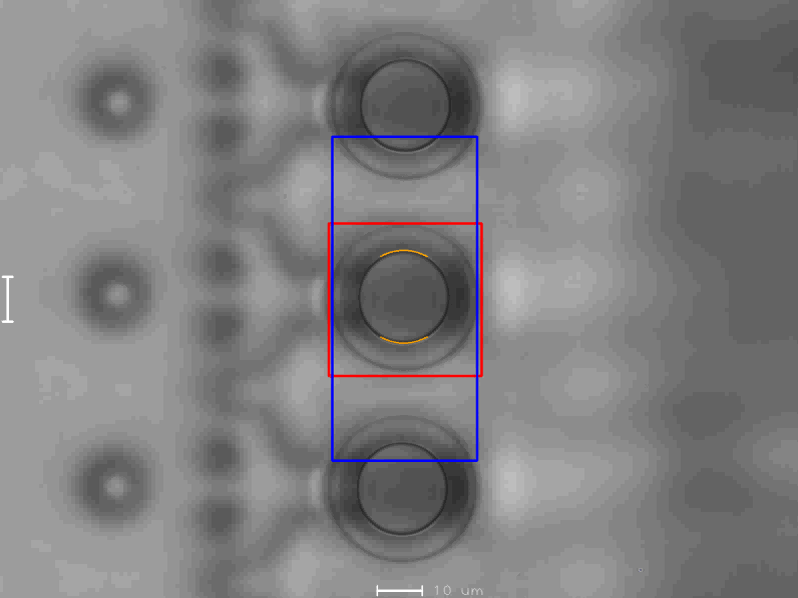

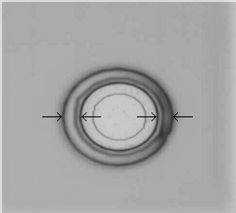

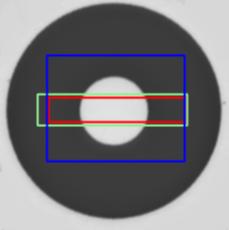

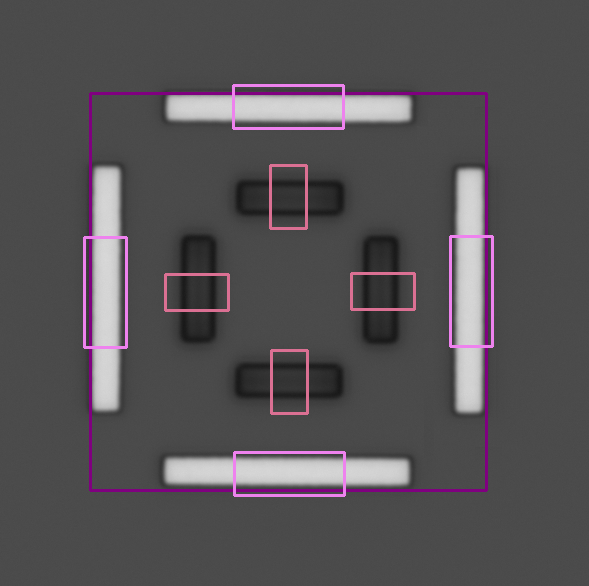

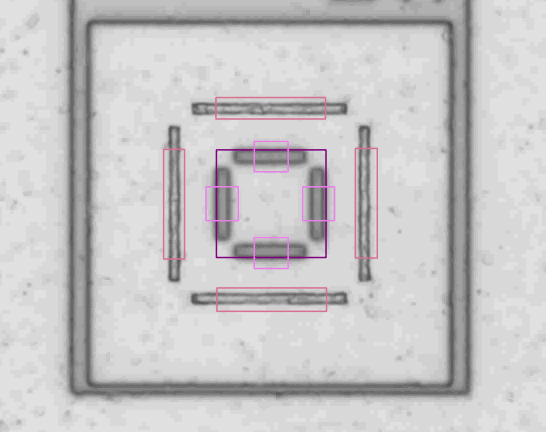

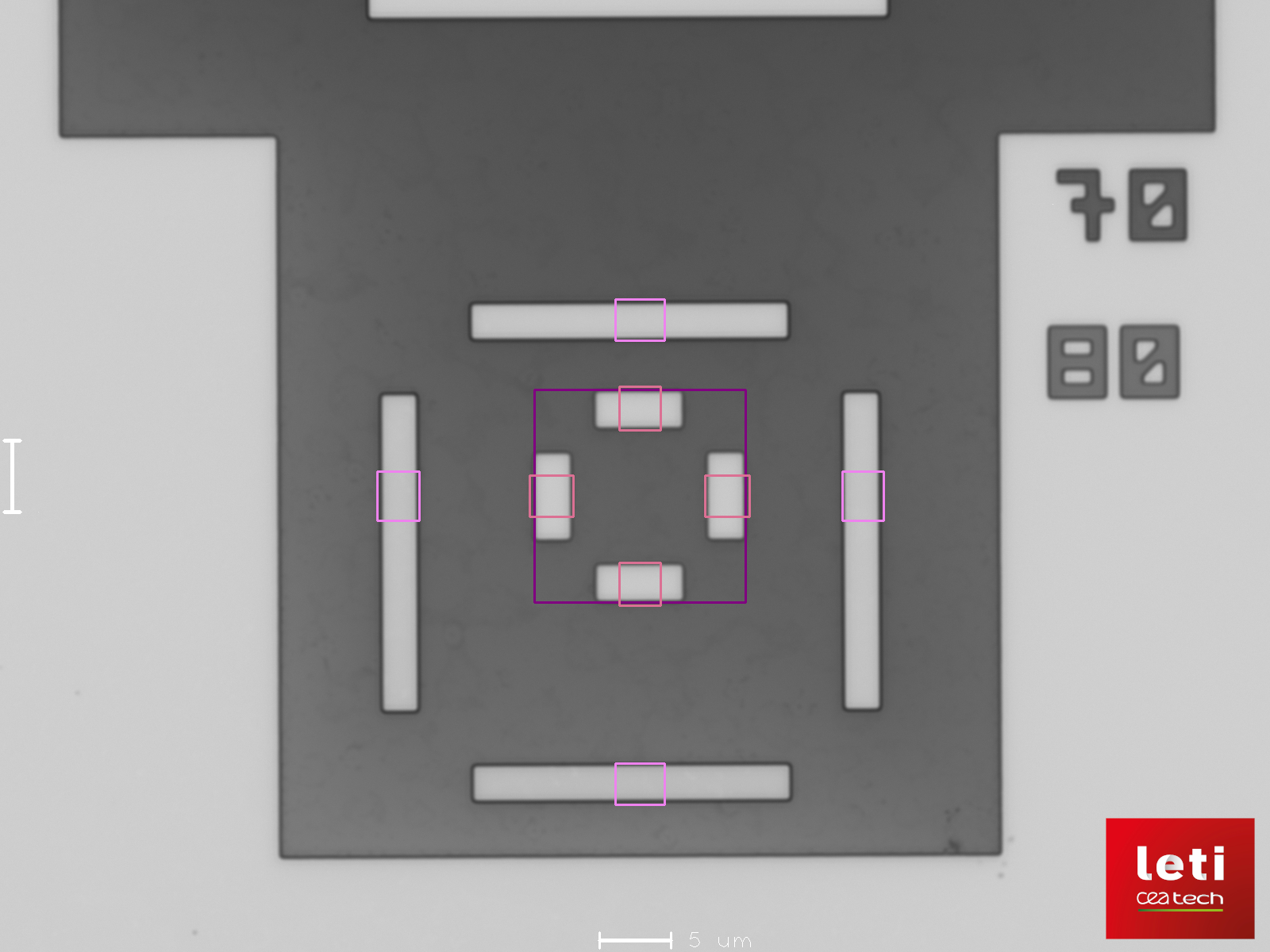

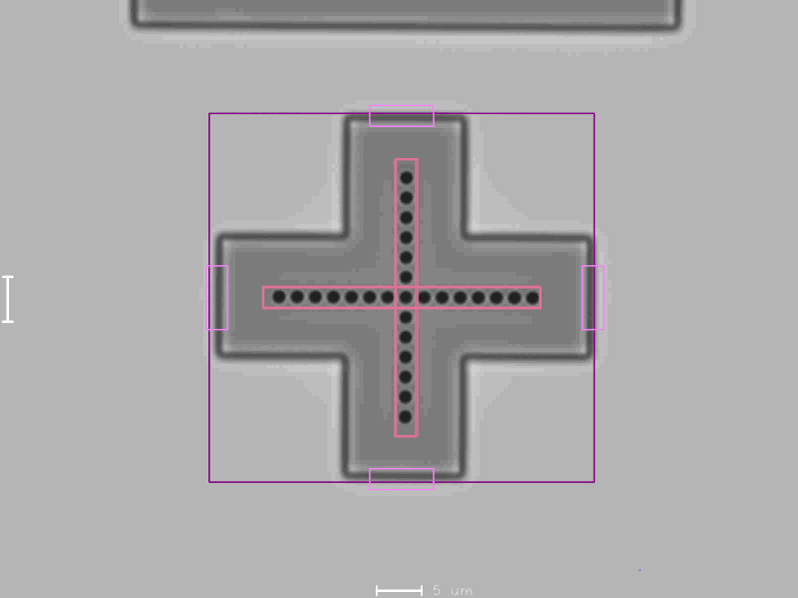

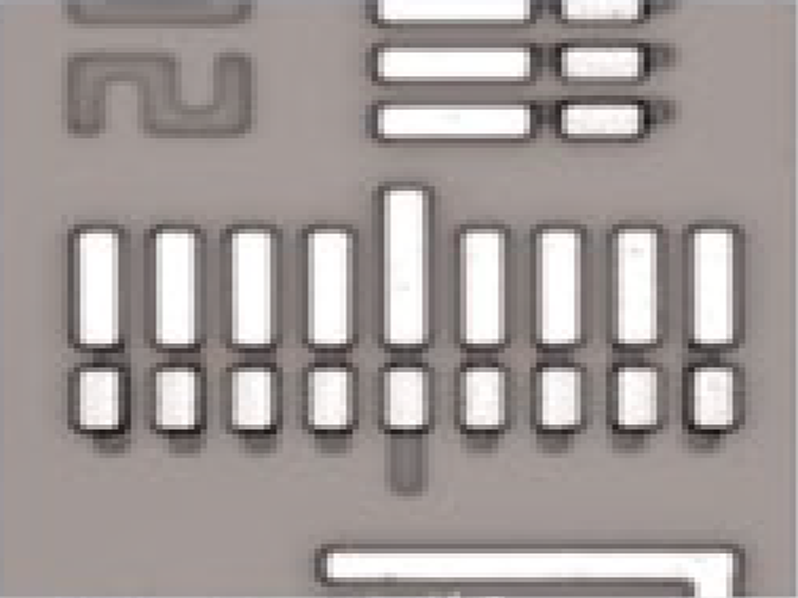

Optical system ready to use to measure critical dimension and overlay registration

EUMETRYS, EUropeanMETRologysYStem company, is a service company supporting automatic metrology systems for semiconductor, compound semiconductor, MEMS and LED factories in Europe.

Thanks to a great number of years of expertise in optical measurement, Eumetrys sells automated optical metrology systems and their spare parts, provides application support, maintenance, and delivers trainings to users for MEMS, semiconductor market (GaAs, GaN, SiC, InP) and LED factories and laboratories.

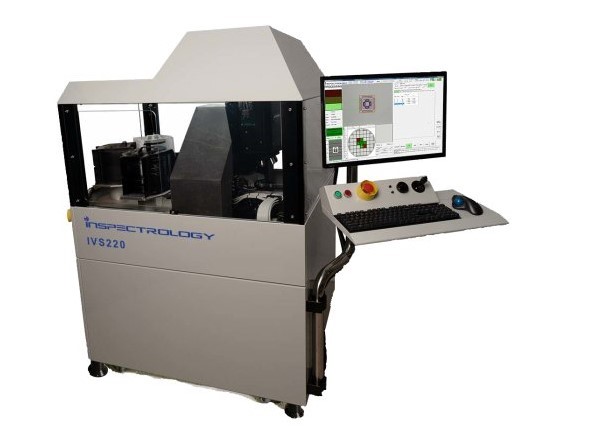

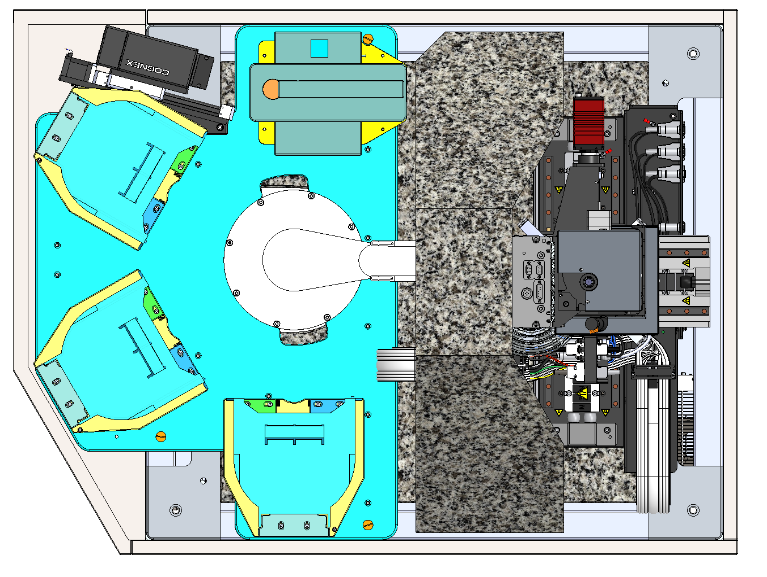

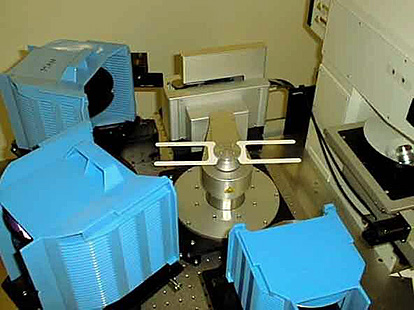

We offer you the last-born of ONTO innovation’s engineering offices: IVS220. At the cutting edge of technology, IVS 220 embeds innovations and features renowned for more than 40 years. New or refurbished, you will find here all technical specifications of the product.

To answer all your needs and budgetary constraints, Eumetrys is able to supply refurbished IVS200 and to guarantee performances of this tool proven by semiconductor industrialists. Click here for more detail

Willing to satisfy new customers as well as historical clients, Eumetrys updates IVS 1.X tools to last generation of IVS200. This solution enables to benefit of last and best performances of the equipment while complying with budgetary constraints of all our customers. Discover the offer here.

Eumetrys is the exclusive distributor in Europe and west Asia of the OEM ONTO innovation LLC. IVS are automatic systems of critical dimension and overlay registration measures.

EUMETRYS, EUropeanMETRologysYStem company, is a service company supporting automatic metrology systems for semiconductor, compound semiconductor, MEMS and LED factories in Europe.

Thanks to a great number of years of expertise in optical measurement, Eumetrys sells automated optical metrology systems and their spare parts, provides application support, maintenance, and delivers trainings to users for MEMS, semiconductor market (GaAs, GaN, SiC, InP) and LED factories and laboratories.

We offer you the last-born of ONTO innovation’s engineering offices: IVS220. At the cutting edge of technology, IVS 220 embeds innovations and features renowned for more than 40 years. New or refurbished, you will find here all technical specifications of the product.

To answer all your needs and budgetary constraints, Eumetrys is able to supply refurbished IVS200 and to guarantee performances of this tool proven by semiconductor industrialists. Click here for more detail

Willing to satisfy new customers as well as historical clients, Eumetrys updates IVS 1.X tools to last generation of IVS200. This solution enables to benefit of last and best performances of the equipment while complying with budgetary constraints of all our customers. Discover the offer here.

Eumetrys is the exclusive distributor in Europe and west Asia of the OEM ONTO innovation LLC. IVS are automatic systems of critical dimension and overlay registration measures.